Nanotronics Smart Factory

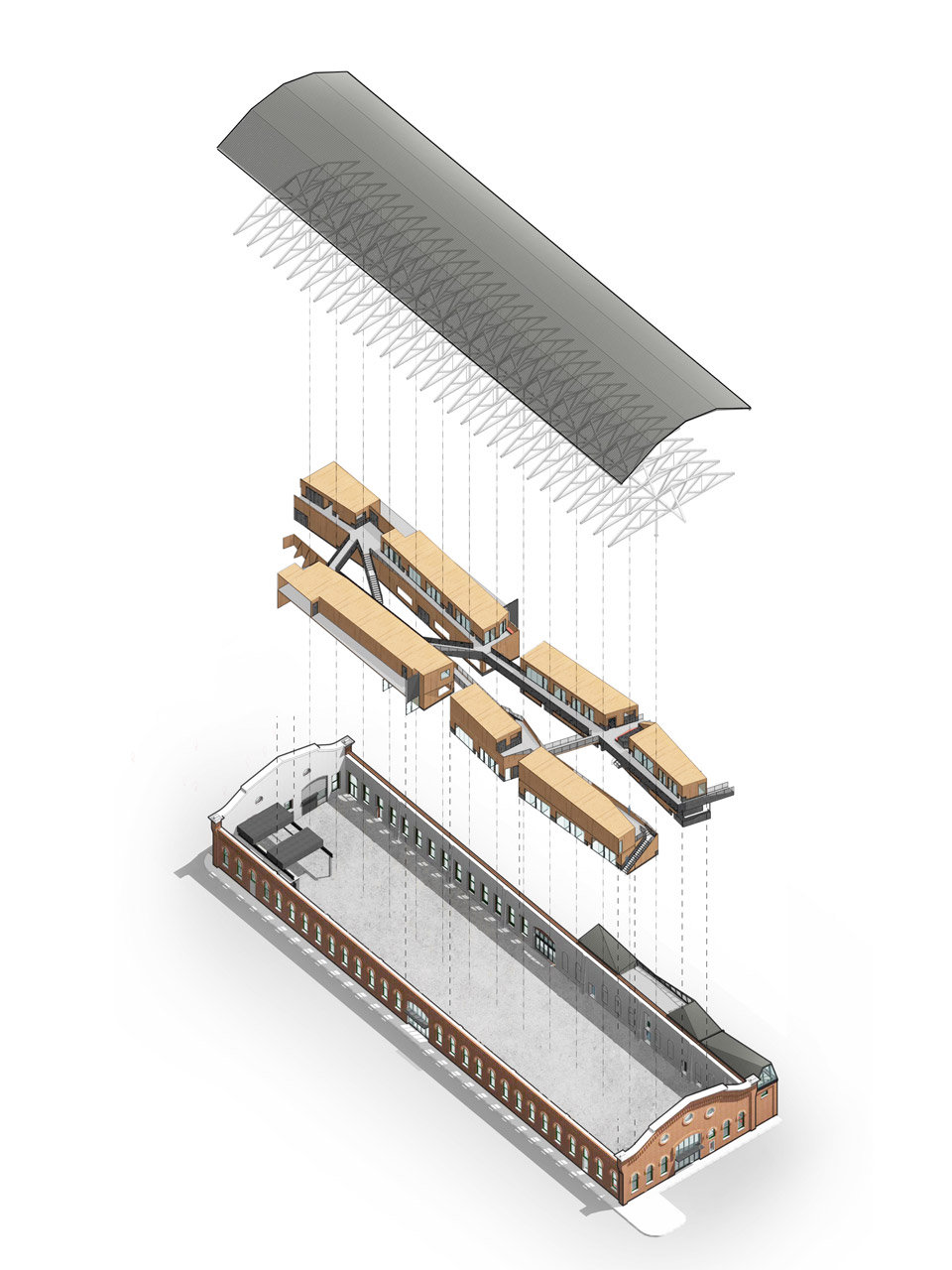

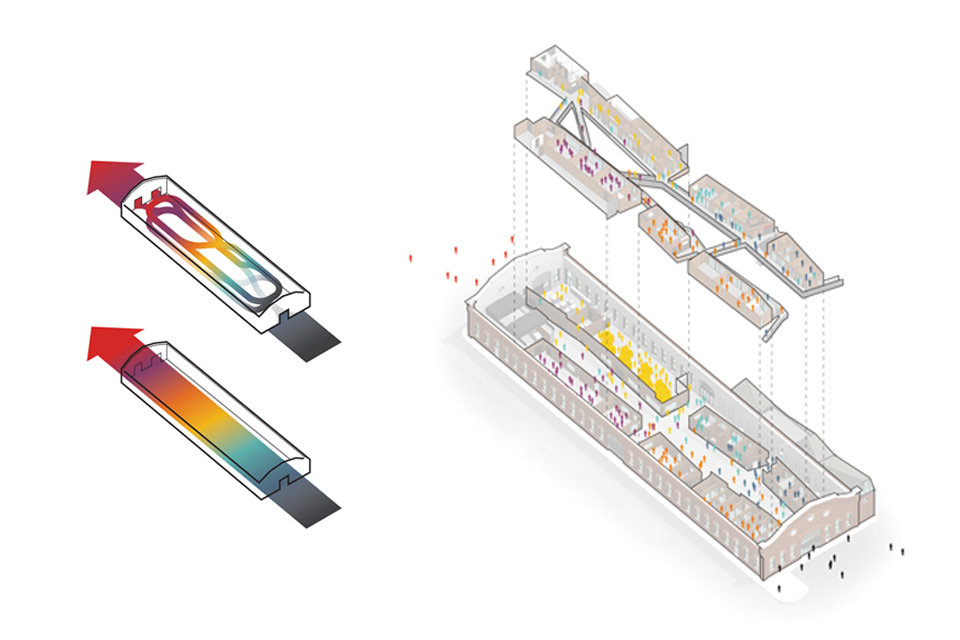

Rogers Partners collaborated with Nanotronics to design its flagship production center, turning a historic Civil War era shipbuilding warehouse in the Brooklyn Navy Yard into a vertically integrated advanced manufacturing facility and headquarters. The design integrates old and new building features as much as it integrates the high-tech production process, creating a fully integrated facility that houses research, design, prototyping, and fabrication under one roof.